Generation and distribution

Large power generators provide an electric current at a potential which can be a few hundred volts or up to about 30 kV. At the power station, transformers step this voltage up to one suitable for transmission.

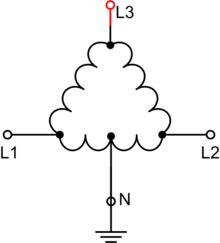

After numerous further conversions in the transmission and distribution network, the power is finally transformed to the standard utilization voltage for lighting and equipment. Single-phase loads are connected from one phase to neutral or between two phases. Three-phase loads such as larger motors must be connected to all three phases of the supply.

Three-wire versus four-wire

Three-phase circuits occur in two varieties. In one case, there are only three energized ("hot") wires; in the other case, there are three hot wires plus a neutral wire. Four-wire circuits offer flexibility, since a load may be connected "line-to-line" or "line-to-neutral"; three-wire circuits offer economy, since the neutral conductor is eliminated. Commonly, distribution voltage circuits are four-wire, while higher voltage transmission circuits are three-wire. Transmission lines often figure a ground wire, but this is solely for lightning protection and is not connected to deliver electrical power.Single-phase loads

Single-phase loads may be connected to a three-phase system in two ways. Either a load may be connected across two of the live conductors, or a load can be connected from a live phase conductor to the neutral conductor. Single-phase loads should be distributed evenly between the phases of the three-phase system for efficient use of the supply transformer and supply conductors. If the line-to-neutral voltage is a standard load voltage, for example 230 volt on a 400 volt three-phase system, single-phase loads can connect to a phase and the neutral. Loads can be distributed over three phases to balance the load. Where the line-to-neutral voltage is not the standard voltage for example 347 volts produced by a 600 V system, single-phase loads are connected through a step-down transformer.In a symmetrical three-phase system, the system neutral has the same magnitude of voltage to each of the three-phase conductors. The voltage between line conductors (Vl) is √3 times the phase conductor to neutral voltage (Vp). That is: Vl = √3Vp.

In some multiple-unit residential buildings of North America, three-phase power is supplied to the building but individual units have only single-phase power formed from two of the three supply phases. Lighting and convenience receptacles are connected from either phase conductor to neutral, giving the usual 120 V required by typical North American appliances. In the split-phase system, high-power loads are connected between the opposite "hot" poles, giving a voltage of 240 V. In some cases, they may be connected between phases of a three-phase system, giving a voltage of 208 V. This practice is common enough that 208 V single-phase equipment is readily available in North America. Attempts to use the more common 120/240 V equipment intended for split-phase distribution may result in poor performance since 240 V heating and lighting equipment will only produce 75% of its rating when operated at 208 V. Motors rated at 240 V will draw higher current at 208 V; some motors are dual-labelled for both voltages.

Where three-phase at low voltage is otherwise in use, it may still be split out into single-phase service cables through joints in the supply network or it may be delivered to a master distribution board (breaker panel) at the customer's premises. Connecting an electrical circuit from one phase to the neutral generally supplies the country's standard single phase voltage (120 V AC or 230 V AC) to the circuit.

The currents returning from the customers' premises to the supply transformer all share the neutral wire. If the loads are evenly distributed on all three phases, the sum of the returning currents in the neutral wire is approximately zero. Any unbalanced phase loading on the secondary side of the transformer will use the transformer capacity inefficiently.

If the supply neutral of a three-phase system with line-to-neutral connected loads is broken, the voltage balance on the loads will no longer be maintained. The neutral point will tend to drift toward the most heavily loaded phase, causing undervoltage conditions on that phase only. Correspondingly, the lightly loaded phases may approach the line-to-line voltage, which exceeds the line-to-neutral voltage by a factor of √3, causing overheating and failure of many types of loads.

For example, if several houses are connected through a 240 V transformer, which is connected to one phase of the three-phase system, each house might be affected by the imbalance on the three phase system. If the neutral connection is broken somewhere in the system, all equipment in a house might be damaged due to over-voltage. A similar phenomenon can exist if the house neutral (connected to the center tap of the 240 V pole transformer) is disconnected. This type of failure event can be difficult to troubleshoot if the drifting neutral effect is not understood. With inductive and/or capacitive loads, all phases can suffer damage as the reactive current moves across abnormal paths in the unbalanced system, especially if resonance conditions occur. For this reason, neutral connections are a critical part of a power distribution network and must be made as reliable as any of the phase connections.

Where a mixture of single-phase 120-volt lighting and three-phase, 240-volt motors are to be supplied, a system called high-leg delta is used.

Three-phase loads

Resistance heating loads such as electric boilers or space heating may be connected to three-phase systems. Electric lighting may also be similarly connected. These types of loads do not require the revolving magnetic field characteristic of three-phase motors but take advantage of the higher voltage and power level usually associated with three-phase distribution. Legacy fluorescent lighting systems also benefit from reduced flicker if adjacent fixtures are powered from different phases.

Large rectifier systems may have three-phase inputs; the resulting DC is easier to filter (smooth) than the output of a single-phase rectifier. Such rectifiers may be used for battery charging, electrolysis processes such as aluminium production or for operation of DC motors.

An interesting example of a three-phase load is the electric arc furnace used in steelmaking and in refining of ores.

In much of Europe, stoves are designed for a three-phase feed. Usually the individual heating units are connected between phase and neutral to allow for connection to a single-phase supply. In many areas of Europe, single-phase power is the only source available.

Phase converters

Occasionally the advantages of three-phase motors make it worthwhile to convert single-phase power to three-phase. Small customers, such as residential or farm properties, may not have access to a three-phase supply or may not want to pay for the extra cost of a three-phase service but may still wish to use three-phase equipment. Such converters may also allow the frequency to be varied allowing speed control. Some railway locomotives are moving to multi-phase motors driven by such systems even though the incoming supply to a locomotive is nearly always either DC or single-phase AC.Because single-phase power goes to zero at each moment that the voltage crosses zero but three-phase delivers power continuously, any such converter must have a way to store energy for the necessary fraction of a second.

One method for using three-phase equipment on a single-phase supply is with a rotary phase converter, essentially a three-phase motor with special starting arrangements and power factor correction that produces balanced three-phase voltages. When properly designed, these rotary converters can allow satisfactory operation of three-phase equipment such as machine tools on a single-phase supply. In such a device, the energy storage is performed by the mechanical inertia (flywheel effect) of the rotating components. An external flywheel is sometimes found on one or both ends of the shaft.

A second method that was popular in the 1940s and 1950s was the transformer method. At that time, capacitors were more expensive than transformers, so an autotransformer was used to apply more power through fewer capacitors. This method performs well and does have supporters, even today. The usage of the name transformer method separated it from another common method, the static converter, as both methods have no moving parts, which separates them from the rotary converters.

Another method often attempted is with a device referred to as a static phase converter. This method of running three-phase equipment is commonly attempted with motor loads though it only supplies ⅔ power and can cause the motor loads to run hot and in some cases overheat. This method does not work when sensitive circuitry is involved such as CNC devices or in induction and rectifier-type loads.

Some devices are made which create an imitation three-phase from three-wire single-phase supplies. This is done by creating a third "subphase" between the two live conductors, resulting in a phase separation of 180° − 90° = 90°. Many three-phase devices can run on this configuration but at lower efficiency.

Variable-frequency drives (also known as solid-state inverters) are used to provide precise speed and torque control of three-phase motors. Some models can be powered by a single-phase supply. VFDs work by converting the supply voltage to DC and then converting the DC to a suitable three-phase source for the motor.

Digital phase converters are designed for fixed-frequency operation from a single-phase source. Similar to a variable-frequency drive, they use a microprocessor to control solid-state power switching components to maintain balanced three-phase voltages.

Alternatives to three-phase

- Split-phase electric power is used when three-phase power is not available and allows double the normal utilization voltage to be supplied for high-power loads.

- Two-phase electric power, like three-phase, gives constant power transfer to a linear load. For loads that connect each phase to neutral, assuming the load is the same power draw, the two-wire system has a neutral current which is greater than neutral current in a three-phase system. Also motors are not entirely linear, which means that despite the theory, motors running on three-phase tend to run smoother than those on two-phase. The generators in the Adams Power Plant at Niagara Falls which were installed in 1895 were the largest generators in the world at the time and were two-phase machines. True two-phase power distribution is essentially obsolete. Special-purpose systems may use a two-phase system for control. Two-phase power may be obtained from a three-phase system using an arrangement of transformers called a Scott-T transformer.

- Monocyclic power was a name for an asymmetrical modified two-phase power system used by General Electric around 1897, championed by Charles Proteus Steinmetz and Elihu Thomson. This system was devised to avoid patent infringement. In this system, a generator was wound with a full-voltage single-phase winding intended for lighting loads and with a small (usually ¼ of the line voltage) winding which produced a voltage in quadrature with the main windings. The intention was to use this "power wire" additional winding to provide starting torque for induction motors, with the main winding providing power for lighting loads. After the expiration of the Westinghouse patents on symmetrical two-phase and three-phase power distribution systems, the monocyclic system fell out of use; it was difficult to analyze and did not last long enough for satisfactory energy metering to be developed.

- High-phase-order systems for power transmission have been built and tested. Such transmission lines use six (two-pole, three-phase) or twelve (two-pole, six-phase) lines and employ design practices characteristic of extra-high-voltage transmission lines. High-phase-order transmission lines may allow transfer of more power through a given transmission line right-of-way without the expense of a high-voltage direct current (HVDC) converter at each end of the line.

- SPACE VECTORSSpace vector representation of the mmf distribution in an AC machine created by balanced positive-sequence three-phase sinusoidal currents. Each of the ABC (RGB) space vectors pulsates along its respective axis. The resultant vector (in black), of 1.5 magnitude, rotates at the excitation frequency.

AC Motors

AC motors are also fairly simple to understand. They are a little trickier to make but will need single-phase or three-phase AC power to make them work. In the little diagrams above, we have a squirrel cage ac induction motor, a permanent magnet synchronous machine, and a synchronous motor. The inventor of the three-phase AC motor was Nikola Tesla, a pioneer in electromagnetism.

Here are some great sites which describe how AC motors work and how to design them.

http://www.motorsoft.net/

http://www.magsoft-flux.com/ (shows a Flux2D animation of the fields within a motor)

http://www.ece.umn.edu/users/riaz/animations/spacevectors.html Great animations!

There are a couple types of basic AC motors you can build. They also make super science fair projects.

http://www.eskimo.com/~billb/maglev/linmot.txt

http://www.italtec.it/enkitmo.htm

A Very Simple AC Motor

Here is a photo of a very simple eddy current AC motor I put together. I think this one wins the prize for the Simplest AC Motor you can make. It works great and is very easy to build. I found the original plans in a book titled: "Physics Demonstration Experiments" by Harry F. Meiners, Vol 2, Ronald Press Co., NY, 1970, LCCC #69-14674. With some experimentation, I found that the can spins faster when the nut is on the end of the bolt than when the nut is removed. What do you think will happen if the rotor is moved to the other side of the bolt? It consists of a coil mounted onto a 3/4" bolt. The coil is about 100' of 20AWG wire, on a form about 1.5" long, with a dc resistance of about 1.2 ohms, and an inductance of about 2.4mH as an air-core inductor. The voltage supplied to the coil is 19Vac from a plug-in transformer and supplies about 2.5Aac to the coil. The rotor is an aluminum film canister (today they use plastic, but you might still find a few of these around - ask your friends) with a dimple in the bottom of it, resting on a pencil. (I figured that the graphite in the pencil will lubricate the rotor.)

The eddy current motor on the left has two rotors, they spin in opposite directions. The set-up on the right shows a variac, multimeter, eddy current motor, and a calibrated strobe. With this, we could plot speed vs. voltage. We found that the rotor would spin about 1000 rpm with 120V applied to it. Can't keep it there for long, since the coil and bolt get real hot. On these two coils, a smaller diameter wire was used, so the dc resistance was about 11.2 ohms, and 24mH as an air-core inductor. With this, we could apply 120Vac to it and only 2 amps would be drawn.

This shows the basic construction. The bolt is a 4" long 3/4-13 bolt, the wood is 3/4" thick. I put a small dimple into the bottom of the aluminum film canister so it would sit onto the pencil point. The red strips of tape helped with the strobe and looks cool as it spins. I found that the nut on the end of the bolt makes it go faster.

A Shaded Pole AC Motor

Here is a photo of a typical shaded pole motor. See the close-up of the notch in the laminations and the extra heavy winding of two turns creating the phase difference between the two sections of the laminations, giving the magnetic field a directional motion. The rotor spins CW as seen from the end with the screw on the shaft. Motors like this are used in thousands of applications.

Another Shaded Pole AC Motor

Here is a photo of a ceiling fan motor, also shaded pole, but with six windings instead of only one as seen above. The rotor laminations are skewed to provide smoother torque. The pole pieces with the windings have a slot in them to create a delayed flux, creating a direction for rotation.

A Universal Motor

And here is a photo of a universal motor. It has brushes like a DC motor, but will operate on AC or DC.

A 3-Phase AC Motor Demonstrator

Here is a project my daughter is working on. It shows how a 3-phase AC motor works with a rotating magnetic field and a permanent magnet rotor, making it a synchronous AC motor. We have pushbuttons which allow the user to turn on any one of the pairs of opposite coils, in either a N-S or a S-N orientation. For example, the green button turns on the horizontal pair of coils in a S-N orientation. The yellow button turns on the horizontal pair of coils in a N-S orientation. On each coil is a bi-color LED to indicate the magnetic polarity of the coil when it is turned on. The power to the coils (each pair connected in parallel) is supplied by a 5v computer power supply. The coils draw about 4amps at 5Vdc each, so a supply with 23amps available is a great match. Each coil is mounted on a 3/4" bolt, attached to a hinge. This way, sets of coils can be folded down out of the way to show how a shaded pole motor works. The rotor is a bar of steel with a NIB magnet on each end. The rotor does oscillate a bit when going from coil to coil.

Here's more photos:

By pressing the colored buttons in the correct sequence, the rotor will follow the magnetic field in a clockwise fashion. The faster you go through the sequence, the faster the rotor will rotate. This shows that the speed of this motor is dependant on the frequency of the power applied to it. The higher the frequency, the faster it goes. At 60Hz, it would rotate at 1 revolution/cycle * 60 cycles/sec * 60 sec/min = 3600 revolutions per minute or rpm.

Three Phase AC Motor Stator

Industrial AC Motors

These are cut-aways of actual industrial three phase AC motors. They have different HP ratings, from 5hp, 2hp, 900hp. They are manufactured by Reliance Electric (used to be part of Rockwell Automation, now part of Baldor Electric).

Linear motors

A linear motor is like an ac motor, but it is unwrapped and laid out flat. The photos show parts of linear motors. Some have flat coils and magnet sections, others are "T" shaped. Check www.anorad.com for more info.

More information is available in these two excellent articles:

http://www-cdr.stanford.edu/dynamic/linear_engine/eng_ref/electric_motors/motion1.pdf

http://www-cdr.stanford.edu/dynamic/linear_engine/eng_ref/electric_motors/motion2.pdf

More on direct drive linear motors:

http://www.ifr.mavt.ethz.ch/publications/sprenger97a.pdf

http://www.ifr.mavt.ethz.ch/publications/sprenger98.pdf

No comments:

Post a Comment